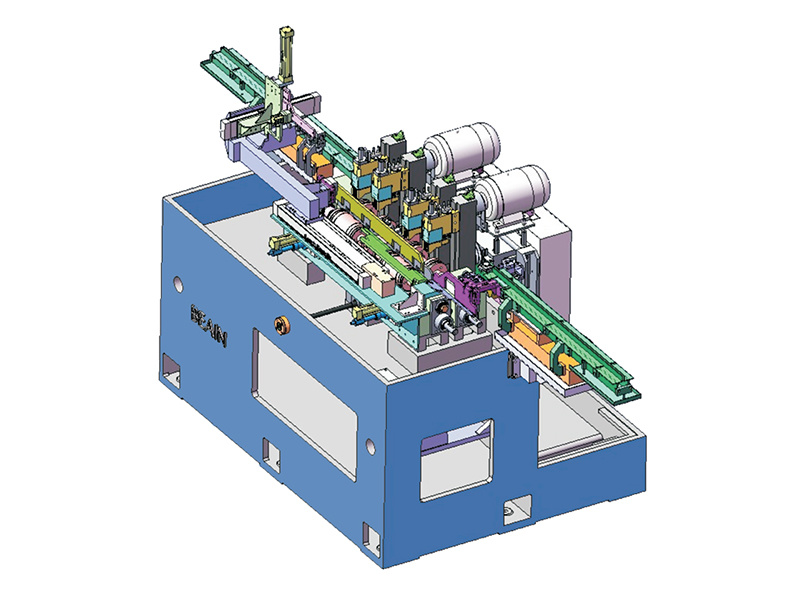

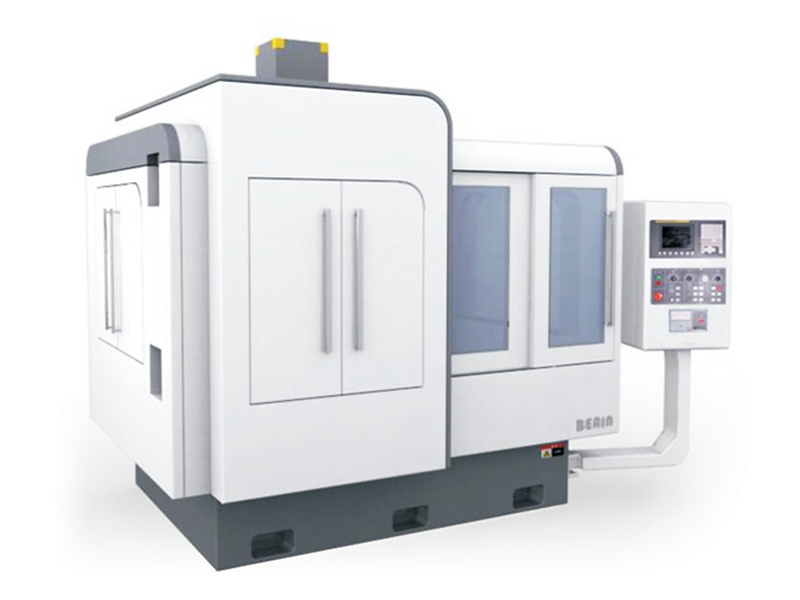

CNC Grinding And Super-Finishing Machines For Generation II Hub Unit Bearing Outer Rings(Taper)

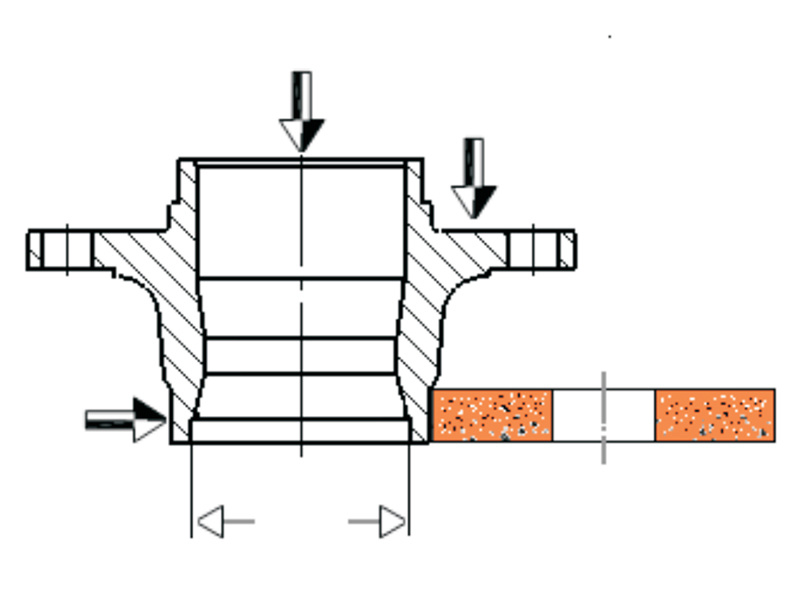

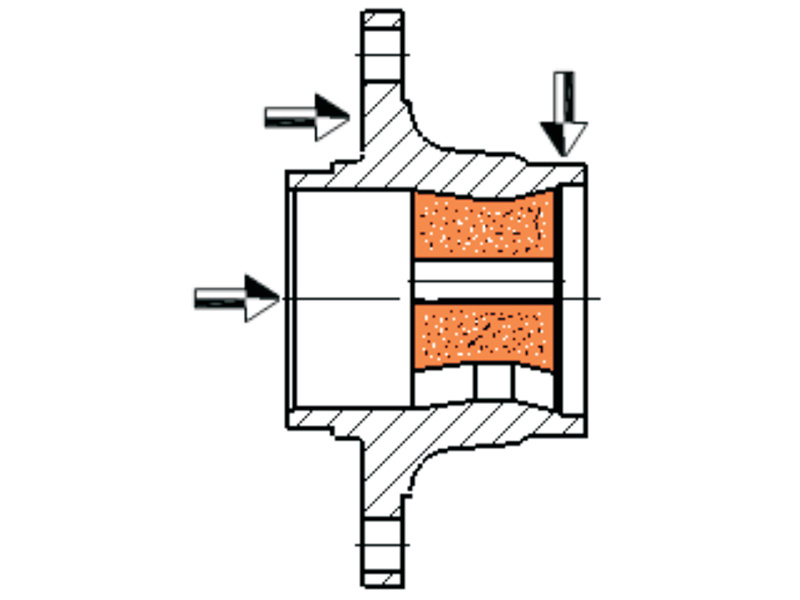

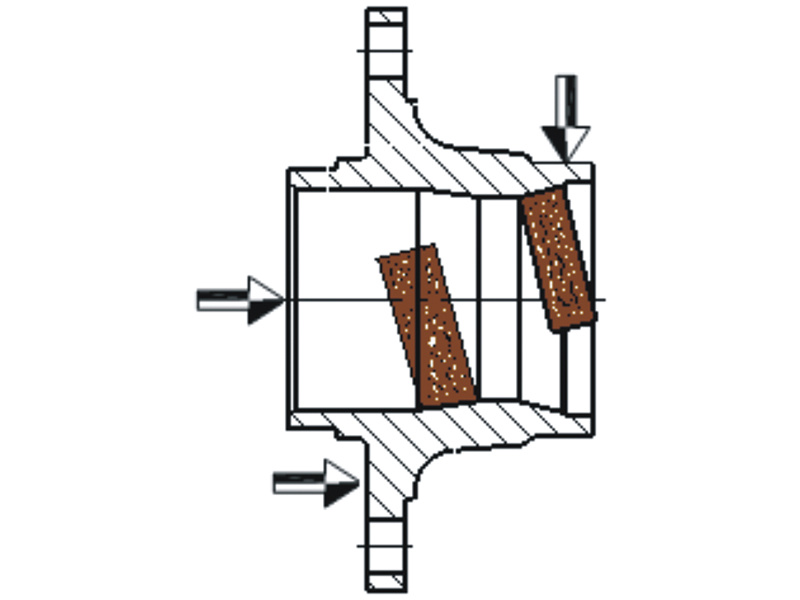

Main application:Grinding and super-finishing of generation Il HUB unit bearing outer rings(Taper)

Categories:

CNC Grinding Machine Series

Email:beainxsb@163.com

|

|

|

|

|

|

Machine model |

3MZ2120CNC |

3MZ2320CNC |

3MZ3420A |

|

Chucking principle |

Magnetic shoe grinding |

Shoe centerless |

|

|

Flange outer diamete |

φ100—φ220 mm |

||

|

Workpiece width |

40—120 mm |

||

|

Grinding wheel speed |

60 m/s |

- |

|

|

Grinding spindles |

Hydro-hybrid spindle |

High frequency spindle |

- |

|

Spindle power |

22 kW |

25 kW |

- |

|

Slides |

Slides with ball screw and servo motor |

||

|

Dressing unit |

Single point diamond pen |

- |

|

|

Super-finishing stone pressure |

- |

- |

0.1-0.4 MPa |

|

Oscillation frequency |

- |

- |

25-20001/min |

|

Super-finishing principle |

- |

- |

One working station,one stone for each track,super-finishing simultaneously |

|

Hydrauic |

1.6-2.2 MPa |

||

|

Pneumatic |

0.3-0.5 MPa |

||

|

Coolant pressure |

0.2-0.5 MPa |

||

|

Coolant flow |

100-200 L/min |

||

|

Machine weight |

7500 kg |

5500 kg |

4000 kg |

|

Machine foot print |

4000*2900*2500 |

3000*3300*2500 |

2950*2900*2200 |

Key words:

CNC Grinding And Super-Finishing Machines

Related Products

A bearing-specific equipment manufacturing company

Fully-Automatic Outer Diameter Super-Finishing Machines For Spherical Roller

Main application:Outer diameter super-finishing of spherical rollers

CNC Outer Diameter Grinding Machines For Spherical And Carb Rollers

Main application:Outer diameter grinding of spherical and CARB rollers

CNC Plunge Super-Finishing Machine For Taper And Cylindrical Rollers

Main application:Super-finishing of cylindrice

Fully-Automatic Super-Finishig Machines For Cylindrical Roller Outer Diameter

Main application:Super-finishing of cylindrical roller outer diameter